In today’s competitive market, businesses prioritize both product protection and visual appeal to attract customers. One of the most effective solutions for achieving both goals is shrink wrap equipment. This advanced packaging technology helps safeguard products from damage while also improving their overall presentation. Whether used in retail, food, pharmaceuticals, or industrial packaging, shrink-wrapping ensures a tamper-proof, professional finish that enhances product longevity and customer confidence.

This article explores how shrink-wrap equipment enhances both product protection and presentation, making it an essential investment for various industries.

The Role of Shrink-Wrap in Product Protection

Ensuring product safety is a top priority for manufacturers and retailers. Shrink-wrapping provides multiple layers of protection that help prevent contamination, tampering, and environmental damage.

1. Prevents Contamination and Tampering

Shrink wrap forms a tight, sealed layer around the product, protecting it from dust, moisture, and bacteria. In industries such as food and pharmaceuticals, where hygiene is paramount, this packaging method ensures that products remain safe and untouched until they reach the end consumer. Additionally, the transparent wrap provides visible proof that the package has been tampered with, enhancing customer trust.

2. Safeguards Against Physical Damage

Products can be easily scratched, dented, or broken during transportation and storage. Shrink-wrapping acts as a protective barrier, securing items and reducing the chances of damage. This especially benefits fragile goods such as electronics, glassware, and cosmetics.

3. Improves Storage and Handling Efficiency

By keeping products tightly packed, shrink-wrap minimizes unnecessary movement, reducing the risk of breakage. It also allows for more compact storage, maximizing warehouse space. Many modern packaging systems include a motorized belt, which ensures smooth and precise handling of products during the shrink-wrapping process, further reducing manual errors and inconsistencies.

Enhancing Product Presentation with Shrink-Wrap

Beyond protection, businesses use shrink-wrap for aesthetic and branding purposes. A well-packaged product stands out on store shelves and leaves a lasting impression on customers.

1. Creates a Professional and Attractive Appearance

Shrink wrap conforms tightly to the product’s shape, giving it a sleek and polished look. Unlike bulky packaging, this method ensures that the product itself remains the focal point. Retailers often prefer this method to maintain an organized and visually appealing display.

2. Customizable for Branding and Marketing

Shrink wrap can be customized with printed designs, company logos, and product details, enhancing brand visibility. Many manufacturers use printed shrink films to incorporate eye-catching graphics, making their products more appealing to consumers.

3. Improves Customer Experience

Customers appreciate clear, well-packaged products that provide transparency about their contents. Whether it’s food items, electronic gadgets, or cosmetics, shrink-wrap ensures that consumers can see exactly what they are purchasing. This reduces uncertainty and enhances buyer confidence.

Applications of Shrink-Wrap Equipment in Different Industries

The versatility of shrink-wrap equipment makes it a preferred packaging choice across various industries.

1. Retail and Consumer Goods

Shrink-wrapping is commonly used for packaging DVDs, books, gift sets, and other retail products. It helps maintain product integrity while preventing dust and damage.

2. Food and Beverage Industry

In the food sector, shrink-wrap plays a critical role in preserving freshness. From baked goods to bottled beverages, this method ensures that products remain safe for consumption while maintaining their visual appeal.

3. Pharmaceuticals and Healthcare

Medicines, medical devices, and personal care products benefit from shrink-wrapping due to its tamper-evident properties. This adds an extra layer of security, ensuring that healthcare products are safe and uncontaminated.

4. Industrial and Manufacturing

Shrink wrap is widely used in manufacturing to bundle products together for easier transportation and storage. It helps prevent dust accumulation and safeguards machinery components during shipping.

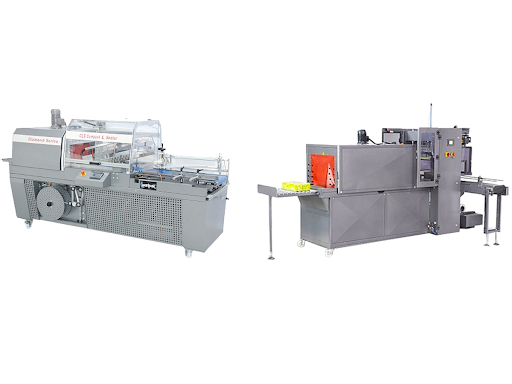

Choosing the Right Shrink-Wrap Equipment

Investing in the right shrink-wrap equipment depends on the specific needs of a business. Several factors should be considered, including:

- Product Type: Delicate or perishable items may require specialized shrink films.

- Packaging Speed: High-volume industries benefit from automated systems with a motorized belt for efficient packaging.

- Film Type: Businesses can choose from PVC, polyolefin, or polyethylene films, depending on the level of durability and transparency required.

Conclusion

Shrink-wrap equipment is a game-changer in modern packaging, offering unparalleled product protection and an enhanced presentation. From preventing damage and contamination to improving visual appeal, shrink-wrapping ensures that products remain secure and attractive. Whether used in retail, food, pharmaceuticals, or industrial packaging, this innovative solution helps businesses maintain quality, increase efficiency, and build customer trust.

By selecting the right equipment and materials, companies can optimize their packaging process and enhance their brand’s overall image in the marketplace.