A gear is a vital component of machinery. A gear is a hard, rigid body with only one function: to move or transmit force from one area of a machine to another.

What do you understand about Gear?

A gear is a blank wheel with many teeth around the edges. The gears have to work in harsh environments. Because of this, it is necessary to make a gear that is strong, durable, very effective, and cost-effective so that it can meet the huge needs of machines.

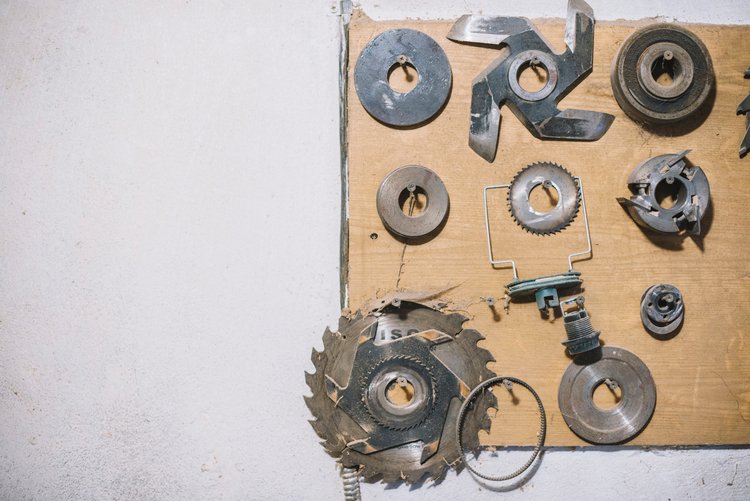

Process of gear cutting

To create or make gears is what gear cutting means. Toothed gears are an important part of mechanical energy transfer, but they need more advanced and methods to be made. Today’s gear-cutting tools make it possible to stamp, cast, machine, or shape gears out of sheet metal.

Cut, hob, grind, or mill gears are the most accurate and right ways to make them in all of these methods. Metal, plastic, or wood are the main materials used to make gears.

Although gears must be cut, a lot of them are produced without cutting (e.g., by injection moulding or die casting), while others must be machined after production.

Five Types of Gear

Rake and Pinion, Worm (with Worm Wheel), Bevel, and Spur are the five primary gear types. In some situations, you need different kinds of gear. The model of their ability to move energy is one way to tell them apart.

Types of Gear Cutting Processes:

The structure of gears makes the method of their manufacture extraordinary. Producing gears is a very unique profession. Gear techniques continue to be practiced today worldwide despite hundreds of years having passed.

The is only for use on machines designed to cut gears.

- Milling: An old milling machine capable of cutting gears, as well as other things, needs modernization. Mass production of gears would not be suitable for it.

- Gear Broaching: A majority of gears are produced by cutting off forms. The process is broaching. The gear is sized by having the broach forced over it, and the teeth of the gear-cutting tools increase slowly. Broaching completes gears and internal splines. Each component employs a distinct broaching tool. Rotary broaching can be performed on any milling machine, CNC lathe, or turning machine to force gears.

- Hobbling Gear: Hobbing quickly and simply produces gear. The business uses hobbing to produce multiple outer cylinder gears. Gear hobbing is a common method of earning money within this business. Because of advanced engineering, more accurate gears—new and old are always in demand. Speed makes this strategy perfect for large to medium events, but also works for very big ones. Gear hobbing machines typically rotate a gear hob and a blank to cut all the teeth.

But since these gear cutting processes are governed by principles, gear blades are employed to form teeth. It states that any two gears will mesh harmoniously with the same pitch, the correct helical angle, the correct tooth depth, and continuity.