As retailers and wholesalers increasingly focus on efficiency and product presentation, bulk packaging solutions are evolving to meet higher standards. Among the most practical and cost-effective options available today is the shrink bundler. Designed for bundling multiple units into a single package, shrink bundlers simplify bulk sales by reducing packaging waste, speeding up the process, and creating tamper-evident, secure wraps.

Whether you’re packaging bottles, cans, boxes, or other multi-item products, shrink bundlers, combined with a reliable heat shrink machine, provide a streamlined solution that balances aesthetics, protection, and production speed. Here’s why they’re the best bet for businesses involved in bulk product distribution.

What Is a Shrink Bundler?

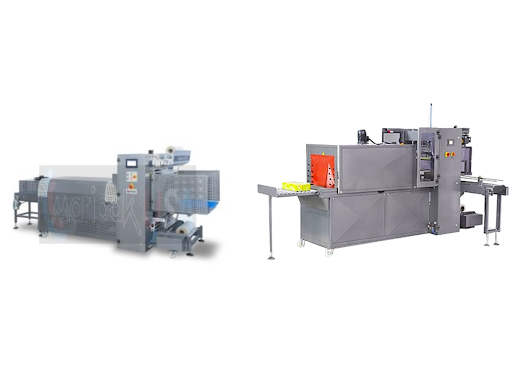

A shrink bundler is a specialized packaging machine that wraps multiple items together using a sleeve of plastic film—typically polyethylene—and then sends them through a heat shrink machine to tightly seal the package. Unlike traditional shrink wrap machines that encase an entire product, shrink bundlers often leave the ends open, forming what’s called a bullseye wrap.

This style of packaging is commonly seen in beverage multipacks (like six-packs of bottled water or soda), but it’s also used for a wide range of consumer goods, including boxed food, personal care items, and household supplies.

Key Advantages of Using a Shrink Bundler

1. Efficient Bulk Packaging

For companies that need to prepare large volumes of goods for wholesale or retail, speed is everything. Shrink bundlers allow multiple items to be packaged in one go, significantly reducing the time spent on individual packaging. The integrated system often includes an infeed conveyor, film dispenser, sealing unit, and heat shrink machine, automating the entire process from start to finish.

2. Cost-Effective Solution

Shrink bundling uses less material compared to individual boxing or wrapping, cutting down on packaging costs. Since polyethylene film is relatively inexpensive and durable, you get strong unit stability without paying a premium for fancy packaging. Labor costs are also lower due to automation.

3. Product Protection and Security

Although shrink bundlers may leave the sides of the package exposed, the bundling film still provides a secure, tamper-evident wrap. It keeps items grouped tightly, reducing the risk of product damage during transportation or storage. When used with a heat shrink machine, the film conforms tightly to the products, ensuring a professional finish.

4. Improved Warehouse and Shelf Organization

Shrink-wrapped bundles make it easier to stack, store, and display products. Retailers appreciate the convenience of pre-bundled items that are shelf-ready or easy to unpack in high-traffic environments. For warehouse distribution, bundled items are less likely to shift or break apart.

5. Eco-Friendly Option

While plastic has a bad reputation in the sustainability conversation, many shrink bundlers now support recyclable films. Using minimal material per unit reduces waste, and some companies opt for biodegradable or recyclable film to align with green initiatives. Bulk packaging itself also contributes to lower overall waste, as fewer individual packages are used.

How the Heat Shrink Machine Complements the Shrink Bundler

The success of a shrink bundling system heavily relies on the performance of the heat shrink machine. After the product is wrapped in film, the heat shrink machine applies uniform heat to shrink the film snugly around the items.

Advanced machines allow operators to control temperature, conveyor speed, and airflow to avoid overheating or incomplete shrinking. These settings are particularly important when bundling heat-sensitive items or using thinner film gauges.

For best results, the heat tunnel must maintain consistent heat levels, and the airflow must be adjusted to ensure tight, wrinkle-free finishes. When synchronized with the bundler, the entire system operates smoothly and efficiently.

Applications in Retail and Industrial Settings

Shrink bundlers are used across industries, including:

- Food and Beverage: Multipacks of bottled drinks, canned goods, or boxed food items.

- Household Products: Bundled paper towels, toilet paper, or cleaning supplies.

- Pharmaceuticals: Unit-dose packs or grouped medication boxes.

- Electronics: Accessory bundles or grouped device packaging.

- Personal Care: Shampoo and conditioner multipacks or cosmetic kits.

For wholesalers and contract packagers, the versatility of a shrink bundler is especially beneficial. The ability to switch between bundle sizes and film types means the same machine can be used across various product lines.

Is It Right for Your Business?

If your operation involves bundling multiple products for distribution or retail sale, investing in a shrink bundler is a strategic move. The reduced labor, lower material costs, improved package integrity, and increased throughput make it an attractive option for growing businesses.

Pairing your bundler with the right heat shrink machine ensures that your finished packages look professional and stand up to the rigors of shipping and shelf display. When integrated properly, this packaging setup becomes a powerful asset in your supply chain.

Final Thoughts

Shrink bundling is no longer reserved for massive production lines. With compact machines and customizable configurations, small and mid-sized businesses can also benefit from this packaging technique. For those focused on bulk sales, a shrink bundler paired with a high-quality heat shrink machine provides speed, consistency, and value that traditional packaging methods often can’t match.